I-jig ivamise ukwakhiwa ngento yokumisa (ukucacisa indawo efanele ye-workpiece endaweni), idivaysi yokulungisa, into eqondisayo yokusika (ukunquma indawo ehlobene yomsiki kanye nocezu lokusebenza noma isiqondiso sokusika isiqondiso), idivayisi ehlukanisayo (ukuze i-workpiece ingaqedela ukucutshungulwa kweziteshi eziningana ekufakweni okubili, okuhlanganisa idivayisi ehlukanisayo ejikelezayo neyomugqa), isici sokuxhuma kanye nomzimba we-fixture (isisekelo sokulungisa), njll.Isibonelo, i-welding jig, i-jig yokuhlola, i-jig yomhlangano, i-jig yomshini, nokunye, okuyinto i-jig yomshini evamile, evame ukufushaniswa njenge-jig.Lapho ucubungula ama-workpieces ethuluzini lomshini.Ukuze wenze ingaphezulu le-workpiece lihlangabezane nezidingo zobuchwepheshe zobukhulu, ubujamo bejometri nokunemba kokuma okuhambisanayo kwezinye izindawo ezicaciswe emidwebeni, ucezu lokusebenza kufanele lumiswe, lubekwe futhi luboshwe ngaphambi kokucubungula.

Izinhlobo ze-jig zingahlukaniswa zibe:① i-jig yendawo yonke. Okufana ne-vise yomshini, i-chuck, i-sucker, ikhanda elihlukanisayo netafula elijikelezayo, njll., linomhlaba wonke omuhle kakhulu. Ingajwayela kahle ukuguqulwa kwezinqubo zokucubungula kanye nezinto zokucubungula.Isakhiwo sayo sibunjiwe, ubukhulu bayo kanye nokucaciswa kwayo kwenziwe nge-serialized, iningi lakho eliye laba insiza evamile yamathuluzi omshini.② I-jig ekhethekile.Idizayinelwe ngokukhethekile futhi yakhiwe ngokwezidingo zokubopha zengxenye yomkhiqizo ngenqubo ethile.Into yesevisi ihlukile futhi iqondiswe kakhulu.Ngokuvamile, iklanywe ngumkhiqizi. Ngokuvamile, faka i-lathe jig, i-jig yomshini wokugaya, i-drilling die (i-jig yethuluzi lomshini lokuqondisa isisiki ukuze sibhoboze noma izimbobo zokuvuselela endaweni yokusebenza), i-boring die (i-jig yethuluzi lomshini lokuqondisa ithuluzi eliyisicefe. imbobo kucezu lokusebenzela) Nokuhambisana nejiji (lokulungisa iselula kulayini ozenzakalelayo wethuluzi lomshini ohlanganisiwe) ③ Ijiji elilungisekayo.Ijigi elikhethekile elingashintshwa noma lilungiselwe izingxenye.④ Inhlanganisela yejig.Jig eyenziwe ngezingxenye ezimisiwe zomumo ohlukene, ukucaciswa kanye ne-USES kufanelekile ukukhiqizwa kwesilingo semikhiqizo emisha kanye nezingcezu zomuntu ngamunye, ukukhiqizwa kwe-batch encane kanye nemisebenzi yesikhashana evame ukushintshwa yimikhiqizo emisha.Ngaphezu kwe-vice, i-chuck, ikhanda elihlukanisayo kanye netafula elijikelezayo, kukhona nomsiki ovamile wokubamba.Ngokuvamile, lapho igama elithi umsiki kanye ne-jig livela ngesikhathi esifanayo, iningi lama-jigs libhekisela kumsiki wesibambo.

lathi jig

Idivayisi ye-jib esetshenziselwa ukucubungula ingaphakathi, ingaphandle kanye nengaphezulu lezinto zokusebenza ku-lathe ibizwa ngokuthi i-jig device ye-lathe.Iningi le-lathe jig ligxunyekwe ku-spindle, ezimbalwa zigibele isihlalo sombhede noma umzimba wombhede.

Umshini wokulinganisa onezixhumanisi ezintathu

Isetshenziswa emshinini wokulinganisa kanye nokwesekwa kwe-modular, idivayisi yereferensi ukuze kufinyelelwe ukulungiswa okuguquguqukayo kwe-workpiece ngaphansi kokuhlolwa.Idivayisi ingase ihlelwe ngokuzenzakalelayo ukuze isekele ucezu lokusebenza futhi imise amaphuzu angenamkhawulo okubhekisela kokucushwa kwe-workpiece.Isofthiwe ekhethekile ekhethekile, engakwazi ngokuqondile ngokusebenzisa idatha yejiyomethri ye-workpiece, ngemizuzwana embalwa ukukhiqiza inqubo yokuhlanganisa i-workpiece.

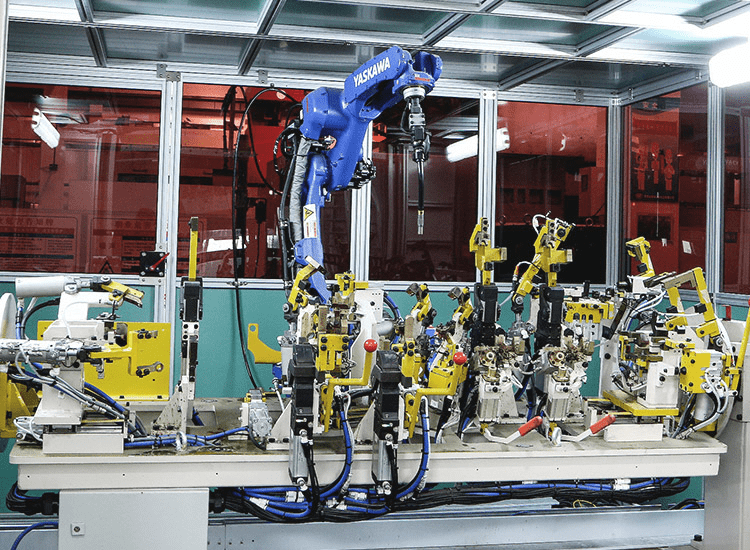

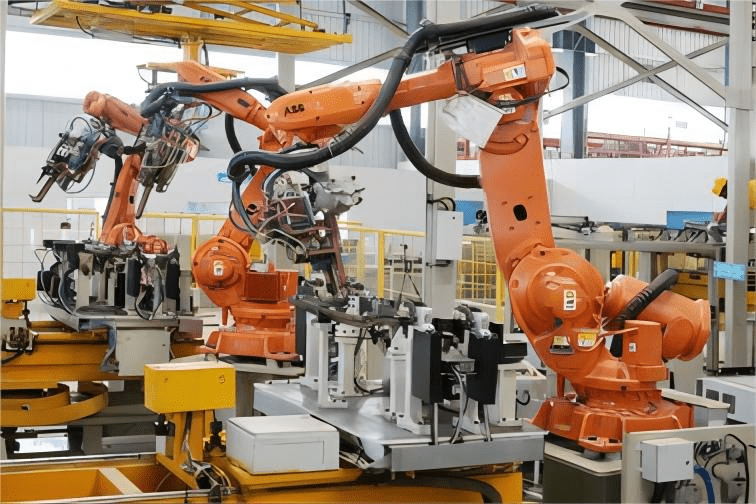

Ukulungiswa kwerobhothi yezimboni

Wonke afakwe kumarobhothi ezimboni futhi asetshenziswa emishinini yezimboni ezishintshayo, okungobunye bobuchwepheshe obusha bemishini yesimanje yezimboni ezishintshayo.Ukubambisana namarobhothi kusetshenziswa kakhulu ekukhiqizweni kwezimboni zesimanje.Ukusetshenziswa okuvamile ukulayisha nokuthulula ithuluzi lomshini, ukupakisha izingcezu zokusebenza, ukushisela, ukugaya nezinye izimboni ezizenzakalelayo ezingenamuntu.

I-Milling jig

Konke kufakwe etafuleni lokugaya, nokunyakaza kokuphakela itafula lomshini. Ikakhulukazi yakhiwe idivayisi yokubeka indawo, idivayisi yokubopha, insimbi yokubopha ukhonkolo, into yokuxhuma kanye neyokusika.Enqubweni yokugaya, amandla okusika makhulu, namandla okusika. isikhashana futhi ukudlidliza kukhulu.Ngakho-ke, amandla okubamba omshini wokugaya makhulu, futhi ukuqina namandla kwedivayisi ye-jig kuphezulu.

Ukuthwala i-pedestal jig

Ukuze kuqinisekiswe ikhwalithi yokukhiqiza ye-bearing pedestal futhi kuthuthukiswe ikhwalithi yokukhiqiza ye-bearing pedestal, ngaphezu kokusebenzisa amathuluzi omshini nezinye izinto zokusebenza zemishini, kuzosetshenziswa inani elikhulu lemishini yezobuchwepheshe. Kubandakanya izimbambo zokubamba, isikhunta, imimese kanye amathuluzi asizayo ahlobene.I-Bearing pedestal jig iyithuluzi lokukhiqiza elisetshenziswa ngokukhethekile ukuze kuqinisekiswe ikhwalithi yokuthwala imikhiqizo yezinyawo.Ingenza inqubo yokukhiqiza yokuthwala i-bearing pedestal ibe lula kakhulu.Izingqimba ezihlukene ze-bearing pedestal zizohluka ngokuya ngezakhiwo zazo ezahlukene kanye namafomu, ukusebenza. izimo kanye nezimiso zokuklama.Ngakho-ke kunezinhlobo nezitayela ezahlukene zesibambi se-ekseli, kokubili ngobuningi nangesitayela.Ingase isetshenziselwe ukunquma ngokunembile ukuma okuhlobene kwendawo yokusebenza.Ngamanye amazwi, ucezu lokusebenza oludinga ukucutshungulwa lungase lusetshenzwe. kuqiniswe, ukuze ukunyakaza okudingekayo ekucubunguleni i-workpiece kungaqedwa.i-fixture of bearing pedestal idlala indima ebaluleke kakhulu enqubweni yokukhiqiza, ngakho-ke kubaluleke kakhulu ukudweba umdwebo we-fixture design.

Isikhathi sokuthumela: Jan-06-2023

.png)

.png)