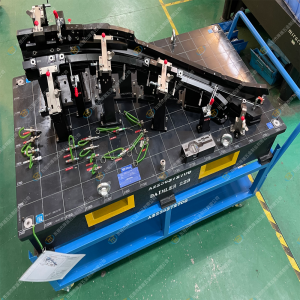

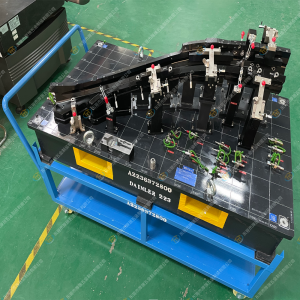

Ukuhlola Ifomu I-Go/No-Go Gages Roof Frame Kwesobunxele Insika Indawo Yokuhlola Ingxenye Yensimbi Eyodwa

Ividiyo

Imininingwane ebalulekile

| Uhlobo Lokulungisa: | Isibaluli/I-CMM Combo Fixture |

| Igama Lengxenye: | Uhlaka Lophahla lushiye Insika ye-LH&RH |

| Thumela Izwe: | EJalimane |

| Ubuningi: | 2 Imisa ingqikithi |

| Okubalulekile: | Insimbi |

Mayelana NATHI

Isingeniso

I-fixture isetshenziselwa kakhulu ukuhlola ukuthi usayizi, ukwakheka, indawo kanye neminye imingcele ye-A-pillar ohlangothini lwesobunxele lohlaka lophahla lwemoto luyahlangabezana nezidingo zokuklama.Kungasiza abakhiqizi bathuthukise ukusebenza kahle kokukhiqiza kanye nekhwalithi yomkhiqizo, futhi banciphise izingozi zokukhiqiza kanye nezinkinga zekhwalithi ezibangelwa ubukhulu be-A-pillar obungahlangabezani nezidingo.

Idizayini kanye nokukhiqizwa kwe-Roof Frame Left A Pillar Checking Fixture kudinga ukucabangela amamodeli ezimoto ahlukene, ngakho ngokuvamile kwenziwa ngendlela oyifisayo.Ngesikhathi senqubo yokukhiqiza, kuyadingeka ukuklama nokucubungula ngokusho kwemidwebo yemodeli kanye nezidingo zokuhlola ezinikezwa ikhasimende.Ngesikhathi esifanayo, ukukhiqizwa kwe-TTM yokuhlola idinga ukulawulwa ngokuqinile ngokuvumelana nesistimu yokuphatha ikhwalithi ye-ISO9001 ukuze kuqinisekiswe ukunemba nokuzinza kwesakhiwo.

Ukugeleza Kwethu Kokusebenza

1. Uthole i-oda lokuthenga———->2. Ukuklama———->3. Ukuqinisekisa umdwebo/izixazululo———->4. Lungisa izinto zokwakha———->5. CNC———->6. CMM———->6. Ukuhlangana———->7. CMM-> 8. Ukuhlola———->9. (ukuhlolwa kwengxenye yesithathu uma kudingeka)———->10. (ngaphakathi/ikhasimende esizeni)———->11. Ukupakisha(ibhokisi lokhuni)———->12. Ukulethwa

Ukubekezela Kokukhiqiza

1. I-Flatness ye-Base Plate 0.05/1000

2. Ukuqina Kwe-Base Plate ±0.05mm

3. Idethi Yendawo ±0.02mm

4. I-Surface ±0.1mm

5. Izikhonkwane Zokuhlola Nezimbobo ±0.05mm

.png)

.png)