Izingxenye zomzimba ezizenzakalelayo zemoto zebhampa yangaphambili Yokulungisa Ukuhlola

Ividiyo

Umsebenzi

Ukuze uthole ukulawulwa kwekhwalithi ye-Front Bumper nokusekelwa ukuze kuthuthukiswe izinga lomthamo wokukhiqiza izimoto

Ukucaciswa

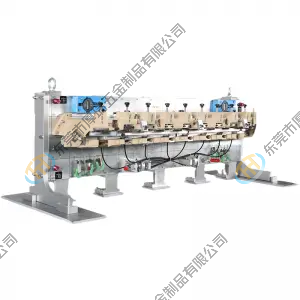

| Uhlobo Lokulungisa: | Ihlola Ukulungiswa Kwebhampa Yangaphambili |

| Usayizi: | 1480*360*600 |

| Isisindo: | 127KG |

| Okubalulekile: | Ukwakhiwa Okuyinhloko: insimbi Ukusekela: insimbi |

| Ukwelashwa kwendawo: | I-Base Plate: I-Electroplating Chromium ne-Black Anodized |

Imininingwane Yomkhiqizo

Isingeniso Esiningiliziwe

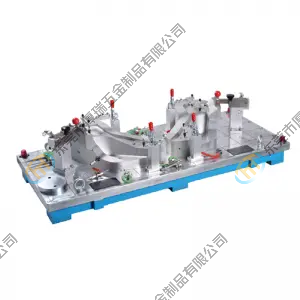

Ithuluzi lokuhlola lidlala indima yokusekela lonke ithuluzi lokuhlola futhi liyisisekelo sethuluzi lokuhlola.Iqinile, izinzile iyisidingo sayo esiyisisekelo.Iphinde idlale indima yokuthwala i-mobile inspection fixture.Amathuluzi okuhlola amakhulu ngokuvamile asakazwa njengohlaka lwamathambo kanye nesisekelo, okudinga ukuba kufakwe irola ephathwayo ekhoneni ngalinye kwamane, ngakho-ke "isisekelo" esiphelele sihlanganisa ipuleti eliphansi, uhlaka lwamathambo kanye nerola, phakathi kwalo ipuleti elingaphansi likhona. kudingekile.Amathuluzi okuhlola amancane nawo awusizo ipayipi lensimbi elishiselwe ohlakeni lokucija, lilula futhi liyasebenza.IZIDINGO EZIngeziwe - Amawasha asentwasahlobo anamandla anele kufanele ahlinzekwe kuzo zonke izinhlobo zokuxhuma okuboshiwe ku-base plate.

Uhlaka lwesakhiwo singaba ngesimo sekholomu ehlukanisiwe uma sisetshenziselwa kuphela ukuhlolwa kwezingxenye zomhlangano.Uxhumano nepuleti elingaphansi lisebenzisa uhlaka lwamathambo oluyisikulufu futhi isisekelo ngokuvamile senziwe ngengxubevange ye-aluminium enomshini wokunemba okuphezulu.I-Shanghai Volkswagen ivamise ukuncoma okwasekhaya: GBZL101.Okubalulekile kufanele kudlule enqubweni yokwelapha ukushisa njengokususwa kwengcindezi: igeji encane isebenzisa ipuleti lesisekelo se-aluminium alloy.

Ingase futhi ihlukaniswe izingxenye ezibonayo (ezifana nendawo esebenzayo) kanye nezingxenye ezingatholi lutho (ezifana nendawo engasebenzi).Izingxenye ze-Automotive trim zangaphakathi nezangaphandle, ikakhulukazi izingxenye zepulasitiki, zinendawo eyinkimbinkimbi yendawo kanye nezici eziningi zendawo, ukuqina okungalungile nezinye izici, okuholela ekumiseni, ekusekeleni nasekubambeni kunzima, ngakho-ke ukuklama kwengxenye yomumo wethuluzi kubaluleke kakhulu.Ngemuva kokuthi ukwakhiwa kwengxenye yomzimba wethuluzi sekuqediwe, indawo kanye nosayizi womhlangano ophansi kunqunywa ngokuvumelana nomzimba wethuluzi, futhi ikhadi lokuma lisethwe esigabeni esiyinhloko okufanele sihlolwe.

Ngempahla yengxenye yomzimba yohlobo, umhloli omkhulu kufanele asebenzise i-resin material (ipulasitiki yobunjiniyela) engacutshungulwa, futhi umhloli omncane angasebenzisa ingxubevange ye-aluminium.

Amaphuzu abalulekile edizayini yemidlalo.

Ngaphambi kokuklama ithuluzi lokuhlola, qiniseka ukuthi ufunda ngokucophelela imidwebo yomkhiqizo, "uqonde kahle" ubukhulu kanye nezidingo ezifanayo zezingxenye, uma kungenzeka, hlola ngokucophelela amasampula kanye nezimoto zesampula, kanye nesakhiwo sangaphakathi sezingxenye ezihloliwe kanye nangaphandle kwazo. ubudlelwano bokusebenzisana -- okokuqala, ukuthola ukuqonda okucacile kwenhliziyo.Isakhiwo sethuluzi lokulinganisa lesimanje kufanele sicatshangelwe ngokugcwele ekwakhiweni kokusetshenziswa kwalo njengesisekelo sokulinganisa (ukusekelwa kokulinganisa kuwuhlobo lokusekelwa okusizayo lapho ukala izingxenye ngomshini wokulinganisa wokuhlanganisa), ukuhlanganisa ithuluzi lokulinganisa kanye nokwesekwa kokulinganisa kube yinye, engakwazi ngokuphumelelayo. londoloza izindleko zokukhiqiza.

Empeleni, indawo yengxenye etholiwe ebekwe ethuluzini kufanele ihambisane nendawo yayo ohlelweni lokudidiyela umzimba, futhi ireferensi yobukhulu kufanele ibekwe ohlelweni lokuxhumanisa umzimba.Qinisekisa ukuthi indiza yereferensi kanye nembobo yereferensi kusisekelo kungasetshenziswa kalula ukuze kusungulwe isistimu yokuhlanganisa ireferensi ehambisana nesistimu yokudidiyela umzimba, okungukuthi, izixhumanisi ezimakwe indiza/imbobo okuyinkomba amanani ohlelweni lokuxhumanisa umzimba. .Umzimba nepuleti eliphansi lethuluzi kuzomakwa njalo ngo-100mm ngezikhombisi-ndlela zika-X, Y kanye no-Z.

Umklami wamathuluzi omuhle kufanele akwazi ukufingqa nokuqonda.Ukwenza isifaniso, kungakhathaliseki ukuthi ibakaki lokulinganisa noma ithuluzi lokulinganisa elincane, ngokwezinga elithile, ukwakheka kwabo kwesakhiwo kufana ne-calligraphy yesiShayina.I-calligraphy yaseShayina inaka indwangu emhlophe, ukujiya okufanele, okuhlakazeke kahle, ukulinganisa, ibhalansi yesokunxele nesokudla, ukuhlanganiswa okuphelele, ubuhle obuphelele.Lokhu kufanele futhi kube njalo lapho uklama i-fixture.izingxenye zezimoto ekukhiqizeni, kuqinisekisa ukuphepha nesivinini sokucubungula sokuhlanganisa izimoto, futhi kuthuthukisa ikhwalithi yezingxenye zezimoto.

Ukugeleza Okusebenzayo

1. Uthole i-oda lokuthenga———->2. Ukuklama———->3. Ukuqinisekisa umdwebo/izixazululo———->4. Lungisa izinto zokwakha———->5. CNC———->6. CMM———->6. Ukuhlangana———->7. CMM-> 8. Ukuhlola———->9. (ukuhlolwa kwengxenye yesithathu uma kudingeka)———->10. (ngaphakathi/ikhasimende esizeni)———->11. Ukupakisha(ibhokisi lokhuni)———->12. Ukulethwa

Ukubekezela Kokukhiqiza

1. I-Flatness ye-Base Plate 0.05/1000

2. Ukuqina Kwepuleti Lesisekelo ±0.05mm

3. Idethi Yendawo ±0.02mm

4. I-Surface ±0.1mm

5. Izikhonkwane Zokuhlola Nezimbobo ±0.05mm

.png)

.png)