I-Welding Fixture For Cross Member WS Spring Link

Ividiyo

Izinkambu Zokusebenza

Ukulawulwa kwekhwalithi yemboni yezimoto

Amandla okukhiqiza ulayini wezimoto ayathuthuka

Ukucaciswa

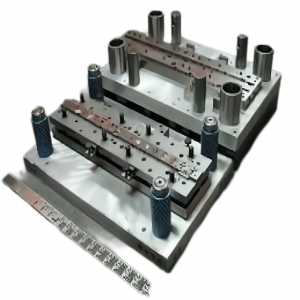

| Uhlobo Lokulungisa: | I-Arc Welding |

| Usayizi: | 1800x1300x900mm |

| Isisindo: | 125KG |

| Okubalulekile: | Ukwakhiwa Okuyinhloko: insimbi Ukusekela: insimbi |

| Ukwelashwa kwendawo: | I-Base Plate: I-Electroplating Chromium ne-Black Anodized |

Imininingwane Yomkhiqizo

Isingeniso Esiningiliziwe

Leli iqoqo le-welding fixture ye-WL Cross Member WS Spring Link, ngokuphelele kumasethi angu-2, esiyenzele ikhasimende lethu laseCanada.I-spring chuck shank iyisigqi esiyisilinda esifakwe emshinini wokugaya ukuze sibophe umshini wokubhola noma wokusika.Faka i-chuck kunothi lokukhiya bese ugoqa ngobumnene inati lokukhiya nge-spring chuck ku-shank, isixhumi noma ukuphotha.Kuya ngokunwebeka kwensimbi enwebekayo ukuze kuqiniswe, i-clamp exegayo ifaneleka, esetshenziswa kakhulu ukubopha ukukhanya, amathuluzi okusika umthwalo ophakathi nendawo.Ivamise ukusetshenziselwa ukuhlanganisa amathuluzi okusika afana nezigayo zokugcina, izinsimbi zokubhoboza, ompompi, ama-reamers kanye nokubhoboza okuphakathi.Shintsha i-clamping range ngokushintsha amaqoqo ahlukene.Lapho ubamba, ingxenye yochungechunge lwe-spring chuck, i-lock nut nendawo yokubeka indawo kanye ne-cone surface kufanele ihlanzwe.Ngesikhathi sokufakwa kwe-chuck ne-lock nut, i-chuck ne-lock nut kumele kutshekiswe ku-Engeli ethile bese kufakwe endaweni yokukhiya nati lokukhiya.Ungayisebenzisi i-torque enwetshiwe ye-wrench enamandla kakhulu, ukuvimbela ithuluzi elibi le-meteorite kanye nesakhiwo.

Ukugeleza Okusebenzayo

1. Uthole i-oda lokuthenga———->2. Ukuklama———->3. Ukuqinisekisa umdwebo/izixazululo———->4. Lungisa izinto zokwakha———->5. CNC———->6. CMM———->6. Ukuhlangana———->7. CMM-> 8. Ukuhlola———->9. (ukuhlolwa kwengxenye yesithathu uma kudingeka)———->10. (ngaphakathi/ikhasimende esizeni)———->11. Ukupakisha(ibhokisi lokhuni)———->12. Ukulethwa

Ukubekezela Kokukhiqiza

1. I-Flatness ye-Base Plate 0.05/1000

2. Ukuqina Kwe-Base Plate ±0.05mm

3. Idethi Yendawo ±0.02mm

4. I-Surface ±0.1mm

5. Izikhonkwane Zokuhlola Nezimbobo ±0.05mm

Inqubo

CNC Machining(Milling/Turning), Ukugaya

I-Electroplating Chromium kanye Nokwelashwa Kwe-Anodized Emnyama

Amahora Wokuklama(h):40h

Amahora Wokwakha(h):150h

Ikhwalithi yokulawula

I-CMM (3D Coordinate Measuring Machine), Vms-2515G 2D Projector, HR-150 A Hardness Tester

Isitifiketi Seqembu Lesithathu senziwa yi-Shenzhen Silver Basis Testing Technology Co., Ltd , ISO17025 Certified

.png)

.png)