TTM Machinery Precision Die And Stamping Part Sample

Ividiyo

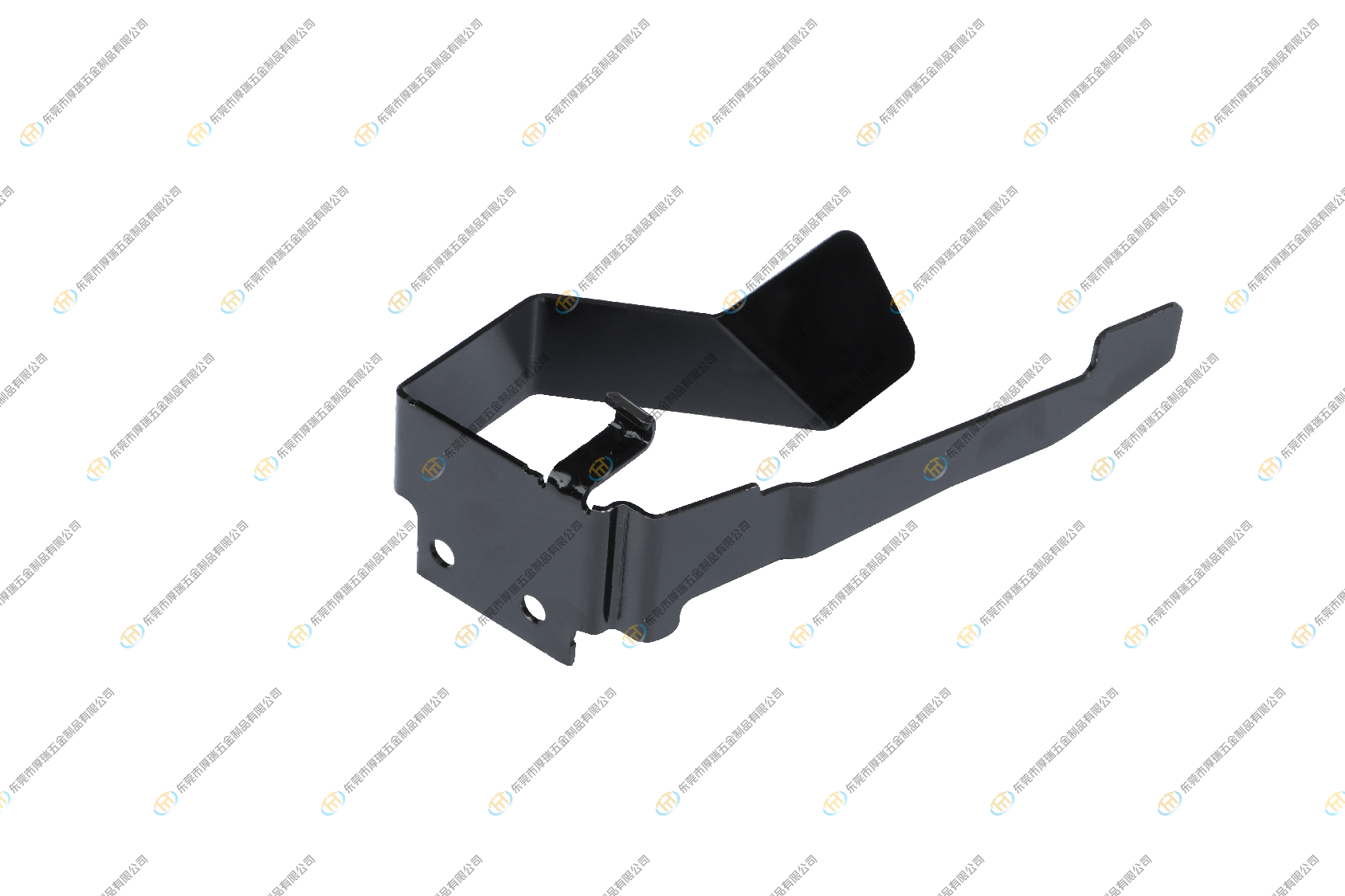

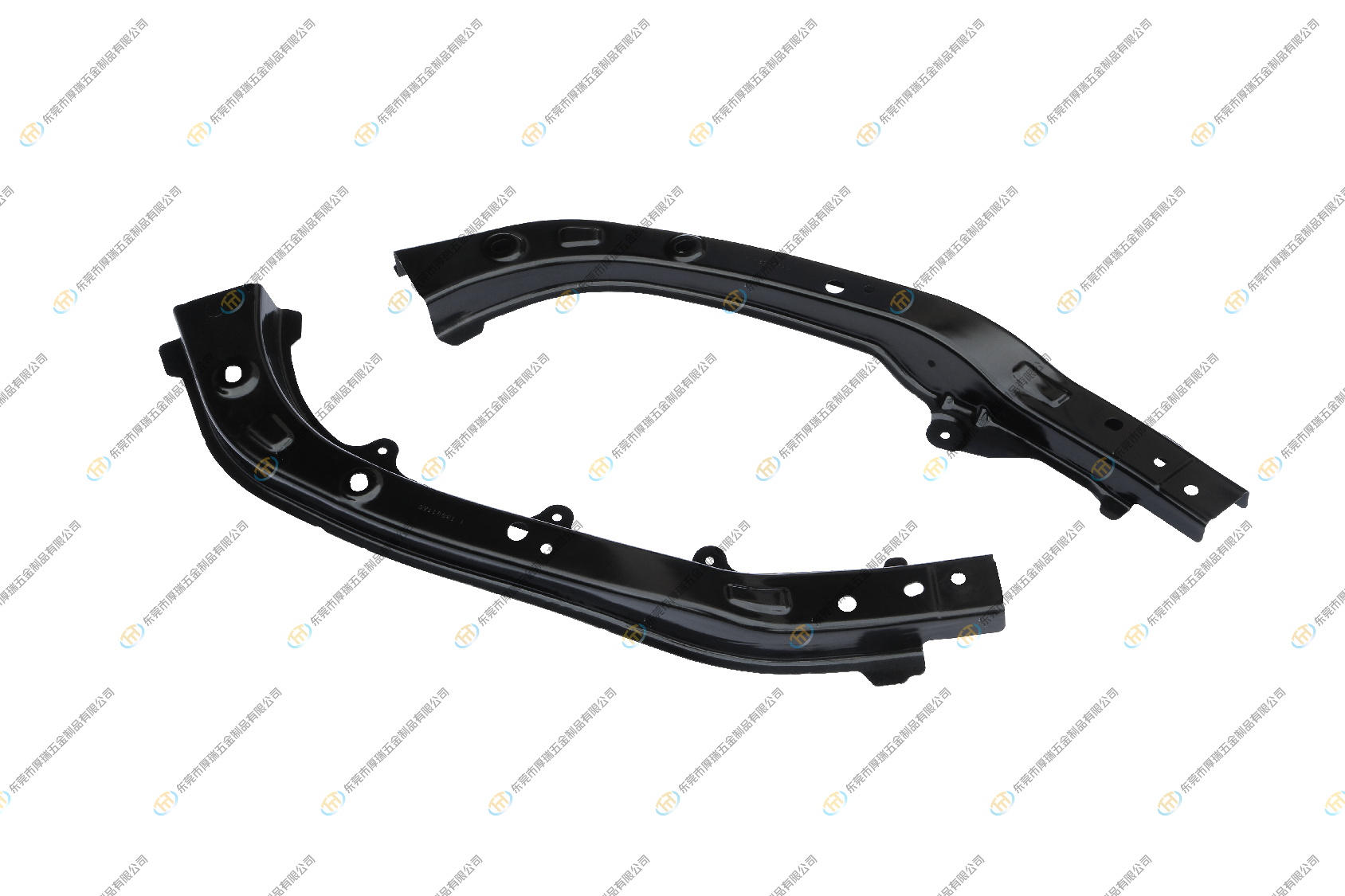

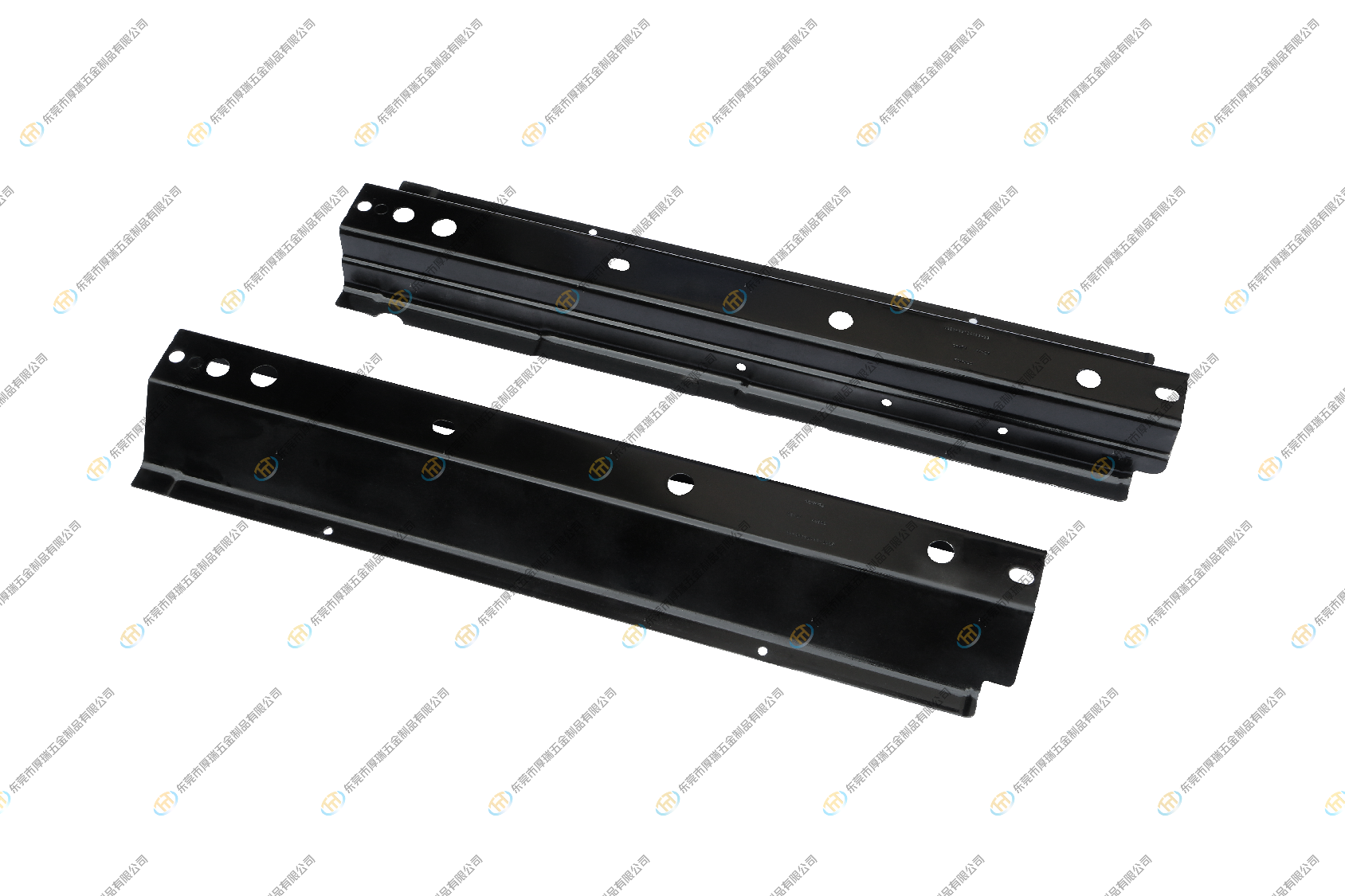

Izingxenye

- Isihlalo emuva

- I-Battery Cradle

- I-Cradle

- Isiteshi esikhulu

- njll.

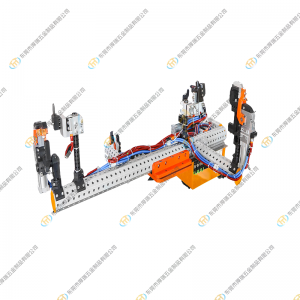

Izithombe Zokukhiqiza

Isingeniso

Izingxenye zokugxiviza zibhekisela ezingxenyeni ezenziwe ngokugxiviza amashidi ensimbi ngokusebenzisa ama-dies.Inezinzuzo zokunemba okuphezulu, isisindo esincane, amandla aphezulu, kanye nezindleko eziphansi, futhi isetshenziswa kabanzi ezimotweni, ezobuchwepheshe, emishinini nakweminye imikhakha.Amasampula engxenye yokugxiviza amanye amasampuli akhiqizwe ngenjongo yokuqinisekisa ukuthi umklamo uyahlangabezana yini nezidingo, ukuhlola ikhwalithi, nokukhangisa imakethe.Ngokuvamile, amasampula ezingxenye zokugxiviza ezikhiqizwe i-TTM adinga ukuhlolwa nokuhlolwa okuqinile ukuze kuqinisekiswe ukuthi ukusebenza kwazo nekhwalithi kuyahlangabezana nezindinganiso futhi kuhlangabezana nezidingo zamakhasimende.

Ukugeleza Kwethu Kokusebenza

1. Uthole i-oda lokuthenga———->2. Ukuklama———->3. Ukuqinisekisa umdwebo/izixazululo———->4. Lungisa izinto zokwakha———->5. CNC———->6. CMM———->6. Ukuhlangana———->7. CMM-> 8. Ukuhlola———->9. (ukuhlolwa kwengxenye yesithathu uma kudingeka)———->10. (ngaphakathi/ikhasimende esizeni)———->11. Ukupakisha(ibhokisi lokhuni)———->12. Ukulethwa

Ukubekezela Kokukhiqiza

1. I-Flatness ye-Base Plate 0.05/1000

2. Ukuqina Kwe-Base Plate ±0.05mm

3. Idethi Yendawo ±0.02mm

4. I-Surface ±0.1mm

5. Izikhonkwane Zokuhlola Nezimbobo ±0.05mm

.png)

.png)