I-TTM Factory Best Inspection Fixtures Car Cross Beam Checking Fixture Design

Ividiyo

Umsebenzi

- Ukuhlolwa kwefomu

- Sika umugqa wokuhlola

- Hamba/cha hamba kuzo zonke izimbobo

- Ukuhlola indawo yembobo

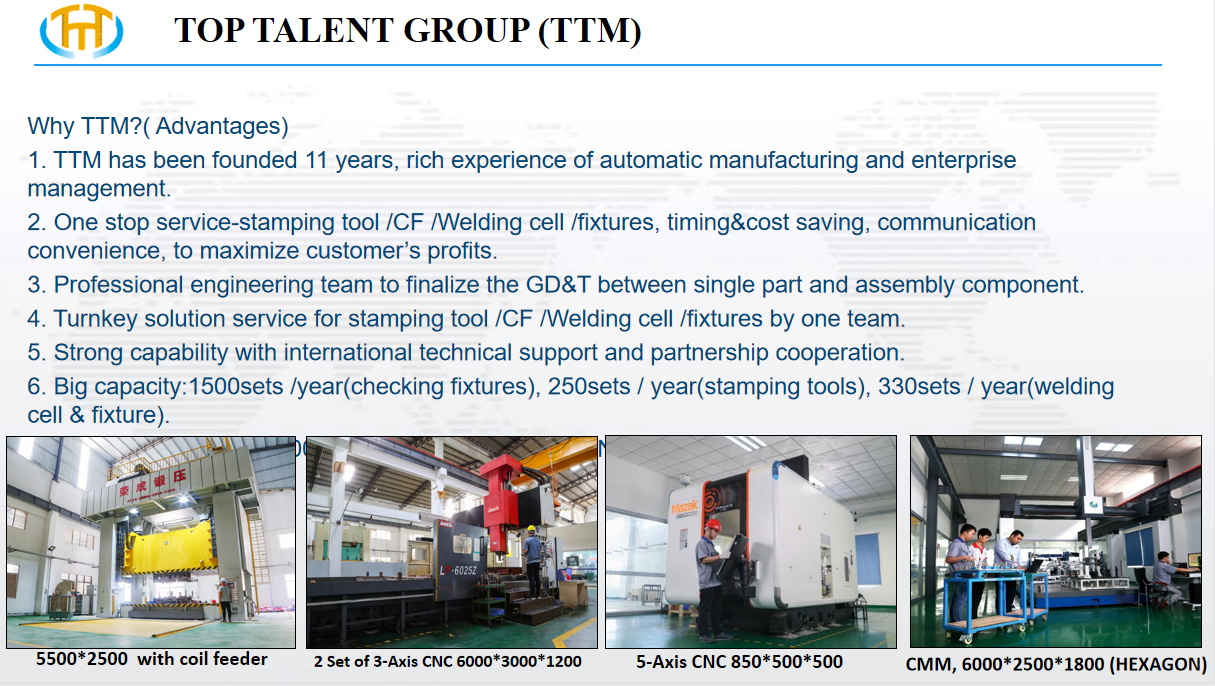

Mayelana NATHI

Sebenzisa

Ngokubeka isigxobo semoto ethuluzini lokuhlola, imingcele ehlukahlukene endaweni enezinhlangothi ezintathu ingatholwa, njengosayizi, isikhundla, ukuma, njll., ukuze kuqinisekiswe ukuthi ikhwalithi nokunemba kwensimbi yemoto ihlangabezana nezidingo.I-Car Cross Beam Checking Fixture isetshenziswa kakhulu ekulawuleni ikhwalithi kanye nezixhumanisi zokuhlola enqubweni yokukhiqiza izimoto, ebaluleke kakhulu ekuthuthukiseni izinga lokukhiqiza izimoto kanye nokunciphisa izindleko zokukhiqiza.

Ukugeleza Kwethu Kokusebenza

1. Uthole i-oda lokuthenga———->2. Ukuklama———->3. Ukuqinisekisa umdwebo/izixazululo———->4. Lungisa izinto zokwakha———->5. CNC———->6. CMM———->6. Ukuhlangana———->7. CMM-> 8. Ukuhlola———->9. (ukuhlolwa kwengxenye yesithathu uma kudingeka)———->10. (ngaphakathi/ikhasimende esizeni)———->11. Ukupakisha(ibhokisi lokhuni)———->12. Ukulethwa

Ukubekezela Kokukhiqiza

1. I-Flatness ye-Base Plate 0.05/1000

2. Ukuqina Kwe-Base Plate ±0.05mm

3. Idethi Yendawo ±0.02mm

4. I-Surface ±0.1mm

5. Izikhonkwane Zokuhlola Nezimbobo ±0.05mm

.png)

.png)