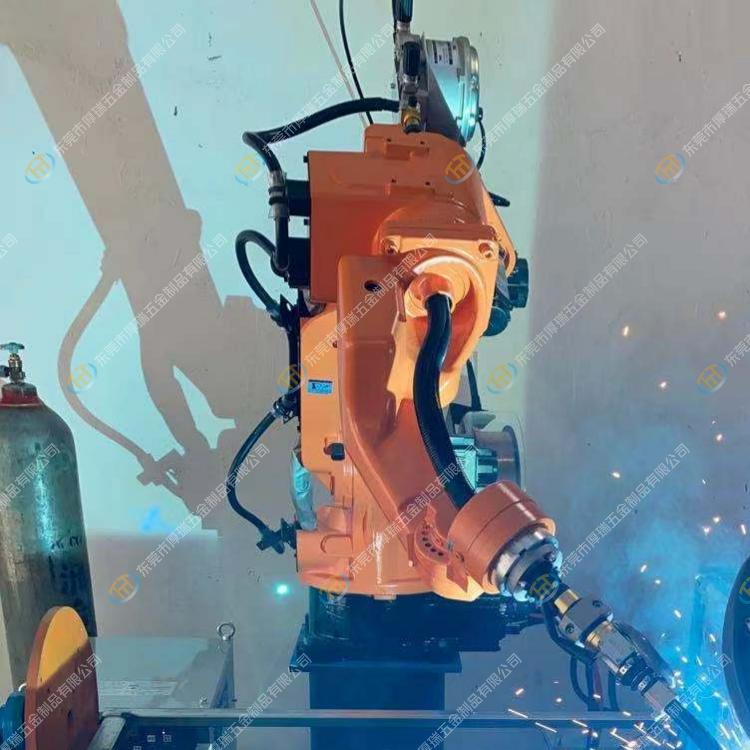

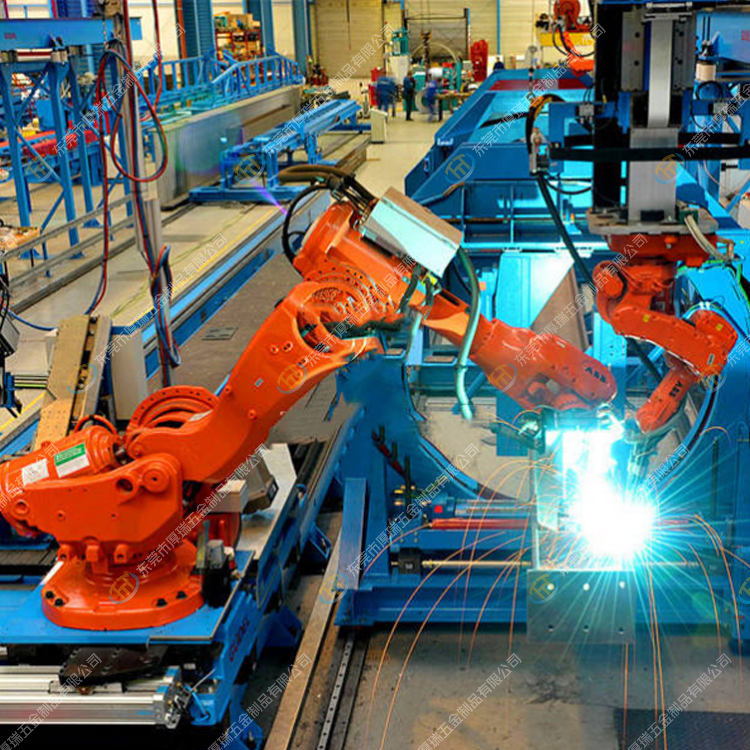

Njengoba ukwakheka kwezimoto kuyinkimbinkimbi kakhulu kunemikhiqizo evamile yemishini, inqubo yokuhlanganisa kanye ne-welding inzima, futhi umthamo wokukhiqiza mkhulu, ikakhulukazi ukukhiqizwa komzimba wemoto bekulokhu kuyimboni enezinhlelo zokusebenza zobuchwepheshe obuphezulu.Ukhiye ikakhulukazi ngamarobhothi amakhulu okushisela nezibali.Umugqa wokukhiqiza we-welding womzimba owenziwe nge-Advancedimishini yokushisela okuzenzakalelayo.  Iningi lomzimba wemoto lakhiwe izingxenye zensimbi nezingxenye zokumboza, kanye nezingxenye zesakhiwo esenziwe ngokwezifiso ngaphambili, njengezinsika ze-windshield, izinsika zeminyango, ama-rails angaphezulu kweminyango, ama-fenders angaphambili nangemuva, amaphaneli angaphambili nangemuva, amakhava aphezulu, njll. zihlanganiswa nge-welding kanye ne-riveting, futhi ukushisela kuyisinyathelo esibalulekile emgqeni womhlangano wezimoto.

Iningi lomzimba wemoto lakhiwe izingxenye zensimbi nezingxenye zokumboza, kanye nezingxenye zesakhiwo esenziwe ngokwezifiso ngaphambili, njengezinsika ze-windshield, izinsika zeminyango, ama-rails angaphezulu kweminyango, ama-fenders angaphambili nangemuva, amaphaneli angaphambili nangemuva, amakhava aphezulu, njll. zihlanganiswa nge-welding kanye ne-riveting, futhi ukushisela kuyisinyathelo esibalulekile emgqeni womhlangano wezimoto.  Eminyakeni yamuva nje, abakhiqizi bezimoto ezinkulu basekhaya bamukele ngokuyisisekeloirobhothi lokushiselaimigqa yokushisela umzimba, futhi eziningana zazo zibonise amandla obuchwepheshe ahamba phambili emhlabeni.Kula marobhothi, amarobhothi ashisela amabala anengxenye enkulu uma kuqhathaniswa.Isibonelo, kuzoba namarobhothi okushisela amabala angaphezu kuka-60 asebenza ku-Jetta A2 body-in-white assembly kanye nolayini wokukhiqiza othomathikhi wokushiselaishabhu yokushiselaye-FAW-Volkswagen Automobile Co., Ltd.

Eminyakeni yamuva nje, abakhiqizi bezimoto ezinkulu basekhaya bamukele ngokuyisisekeloirobhothi lokushiselaimigqa yokushisela umzimba, futhi eziningana zazo zibonise amandla obuchwepheshe ahamba phambili emhlabeni.Kula marobhothi, amarobhothi ashisela amabala anengxenye enkulu uma kuqhathaniswa.Isibonelo, kuzoba namarobhothi okushisela amabala angaphezu kuka-60 asebenza ku-Jetta A2 body-in-white assembly kanye nolayini wokukhiqiza othomathikhi wokushiselaishabhu yokushiselaye-FAW-Volkswagen Automobile Co., Ltd.  Eminyakeni yamuva, ubuchwepheshe bomzimba we-laser welding kancane kancane buthathe indawo yobuchwepheshe bokushisela indawo yokumelana, obungakwazi ukuhlangabezana nezidingo eziphelele ekucubunguleni izingxenye zezimoto.Ukusebenzisa lobu buchwepheshe obusha, ububanzi obuhlangene bobuso phakathi kokuxhumeka kwe-workpiece bungancishiswa, okungagcini nje ukunciphisa isidingo samapuleti Futhi kwandisa ukuqina komzimba.Izingxenye zokushisela i-laser, ngokuyisisekelo akukho deformation ezingxenyeni zokushisela zezingxenye, isivinini sokushisela siyashesha, futhi asikho isidingo sokwelashwa kokushisa kwangemva kokushisela.I-laser welding inamandla amahle mayelana nokusebenza kahle, umnotho, ukuphepha, amandla, nokumelana nokugqwala.Futhi lobu buchwepheshe obusha sebuphenduke futhi imishini eyimishini esetshenziswayo embonini yokukhiqiza yezimboni.

Eminyakeni yamuva, ubuchwepheshe bomzimba we-laser welding kancane kancane buthathe indawo yobuchwepheshe bokushisela indawo yokumelana, obungakwazi ukuhlangabezana nezidingo eziphelele ekucubunguleni izingxenye zezimoto.Ukusebenzisa lobu buchwepheshe obusha, ububanzi obuhlangene bobuso phakathi kokuxhumeka kwe-workpiece bungancishiswa, okungagcini nje ukunciphisa isidingo samapuleti Futhi kwandisa ukuqina komzimba.Izingxenye zokushisela i-laser, ngokuyisisekelo akukho deformation ezingxenyeni zokushisela zezingxenye, isivinini sokushisela siyashesha, futhi asikho isidingo sokwelashwa kokushisa kwangemva kokushisela.I-laser welding inamandla amahle mayelana nokusebenza kahle, umnotho, ukuphepha, amandla, nokumelana nokugqwala.Futhi lobu buchwepheshe obusha sebuphenduke futhi imishini eyimishini esetshenziswayo embonini yokukhiqiza yezimboni.

Isikhathi sokuthumela: May-12-2023

.png)

.png)