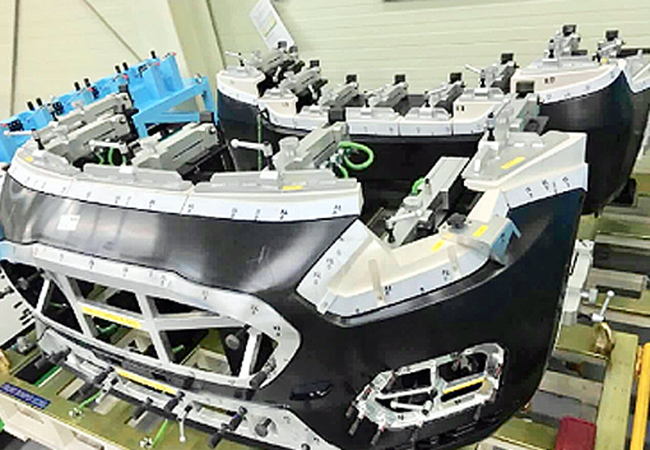

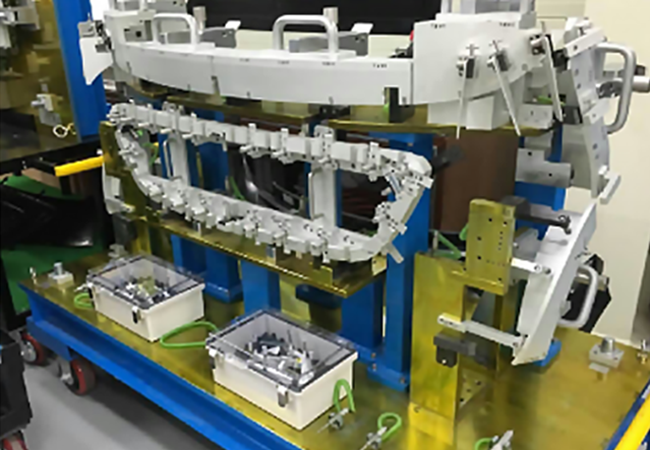

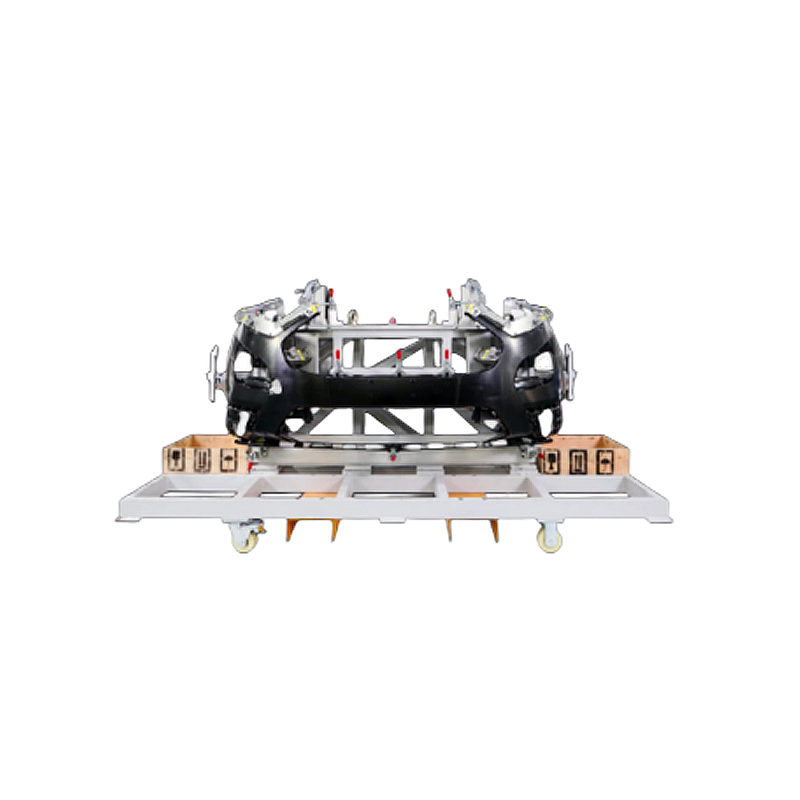

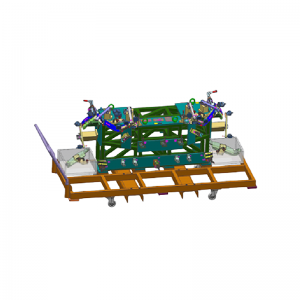

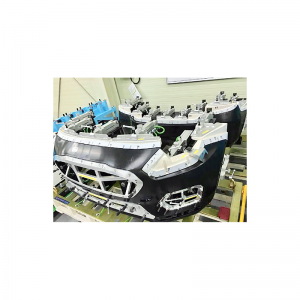

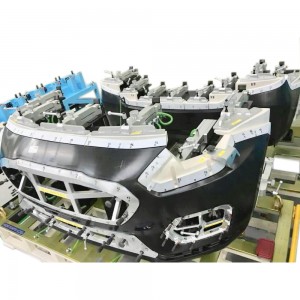

Ibhampa yangaphambili ye-ASSY yokuhlola ukulungiswa

Ividiyo

Umsebenzi

Hlola into yokuhlanganisa amabhampa angaphambili.Leli ithuluzi lokuhlola izingxenye zemoto zangaphambili zebhampa, ukuze kungenelwe amathuluzi okulinganisa angochwepheshe, njengegeji yepulaki ebushelelezi, igeji yepulaki eyisikulufu, igeji ye-diameter caliper gauge nokunye ukuze kutholwe ukuhlangana kwebhampa yangaphambili, ukuze kwahlulele ukuthi izingxenye zifanelekile yini.

Izinkambu Zokusebenza

Ukulawulwa kwekhwalithi yemboni yezimoto.

Amandla okukhiqiza ulayini wezimoto ayathuthuka.

Ukucaciswa

| Uhlobo Lokulungisa: | Ukuhlola Izingxenye Zepulasitiki Zomhlangano |

| Usayizi: | 1450*980*1180 |

| Isisindo: | 145KG |

Imininingwane Yomkhiqizo

Isingeniso Esiningiliziwe

Lesi isihluthulelo sokuhlola ibhampa yangaphambili ye-ASSY, ehlanganisa: ithebula litholakala nhlangothi zombili zebhentshi lokusebenzela, futhi ngokusebenzisa iphinikhodi yokusekela yabakaki bokuqala, iphini lokubeka indawo yokugqoka isikafula kubha ngaphambi kokuhlanganisa: setha ibha ngaphambi kwabakaki bokuqala. kanye nokumelana nomhlangano wabakaki kuqala indiza ethile kanye nendawo yesibili yendawo: abakaki besibili, abakaki besibili banendawo yesithathu engahambisani yokubeka ama-stents kubha ngaphambi komhlangano: Isihlalo sesithathu sokusekela: kanye nomhlangano wengcindezi ephendukayo ohlelwe engxenyeni engenhla. yomhlangano wokusekela kubha engaphambili yetafula lokusebenza: lapho, isihlalo sesithathu sokusekela, indawo yesibili yokuma nendawo yesithathu yokuma kufakwe ngendlela enyakazayo nephinikhodi yokuhlola engadlula embotsheni ekhwezayo yomhlangano wokusekela kubha engaphambili. .Imodeli yensiza isebenzisa izikhonkwane zokumisa ukuze kutholwe ukuhlangana kosekelo kubha engaphambili, futhi iqondaniswe nendawo ngayinye yokuma, bese icindezela futhi ikhiye ingxenye ngokuyiphendula, futhi ekugcineni isebenzisa iphinikhodi ngayinye yokubona ukuze kutholwe ukuthi imbobo yokufaka yokuhlanganisa yokusekela Ibha engaphambili ihambisana, ukuze ugweme inkinga yokutholwa okuyisicefe kanye nephutha esikhathini esidlule.Imodeli yokusetshenziswayo ihlobene nethuluzi lokuhlola umhlangano wemoto wangaphambili, ohlanganisa isisekelo samathuluzi okuhlola, lapho ibhulokhi yokuthola indawo kanye i-hole discovery block ihlelwa ngokulinganayo.Inezici ezilandelayo: isisekelo sendawo ngemuva kokubeka i-log yembobo yembobo yokusebenzela ngembobo yesiqeshana sokusebenza, ucezu lokusebenza okufanele ukhawulelwe, kubhulokhi yokutholwa kobuso kuzo zombili iziphetho ze-workpiece, futhi ugcine igebe elithile ngokutholwa kobuso. ibhulokhi, kusetshenziswa ucezu lwendawo yokuhlola ithuluzi lokulinganisa luphetha ngegebe lendiza elingaphansi kwendawo yokusebenza phakathi kwabampofu kanye nama-artifact ebhulokhi elitholwa ngembobo endaweni yezimbobo ezifakwayo.Imodeli yensiza inezinzuzo zesakhiwo esilula, hhayi kuphela ukuqinisekisa ukwesekwa kwayo okuthembekile nokuzinzile, ukutholwa okulula okusheshayo nokunembile, kodwa futhi nokwenza lula ukwakheka kwayo, futhi ngaleyo ndlela ithuthukise kakhulu ukusebenza kahle kokukhiqiza kwabasebenzi.

Ukugeleza Okusebenzayo

1. Uthole i-oda lokuthenga———->2. Ukuklama———->3. Ukuqinisekisa umdwebo/izixazululo———->4. Lungisa izinto zokwakha———->5. CNC———->6. CMM———->6. Ukuhlangana———->7. CMM-> 8. Ukuhlola———->9. (ukuhlolwa kwengxenye yesithathu uma kudingeka)———->10. (ngaphakathi/ikhasimende esizeni)———->11. Ukupakisha(ibhokisi lokhuni)———->12. Ukulethwa

Amasevisi Angemuva Kokuthengisa

A. Ukuhlinzeka Ngemibhalo Nokuqeqeshwa Kwezobuchwepheshe

B. Ukuhlinzeka ngohlu lwezingxenye eziyisipele

C. Izinsimbi Ezinconyiwe Nezingxenye Zokushintsha

D. Ukwethembeka kanye Nokugcinwa

E. Ukufakwa Kwezisetshenziswa Esizeni Sekhasimende

F. Ukwesekwa Kwelayini Lasekhaya/Ukukhiqiza

G. Ukusekelwa Okukude Kwezobuchwepheshe Kwekhomishini/Ukuxazulula Izinkinga Esizeni Sekhasimende

Inqubo

CNC Machining(Milling/Turning), Ukugaya

I-Electroplating Chromium kanye Nokwelashwa Kwe-Anodized Emnyama

Amahora Wokuklama(h):40h

Amahora Wokwakha(h):150h

Ikhwalithi yokulawula

I-CMM (3D Coordinate Measuring Machine), Vms-2515G 2D Projector, HR-150 A Hardness Tester

Isitifiketi Seqembu Lesithathu senziwa yi-Shenzhen Silver Basis Testing Technology Co., Ltd , ISO17025 Certified

.png)

.png)