Umkhiqizi we-Automotive Welding Fixture Manufacturer Nefekthri Engcono Kakhulu E-China

Ukuthuthukiswa Kwenkampani

- Ngo-2011, i-TTM yasungulwa eShenzhen.

- Ngo-2012, Ukuthuthela e-DongGuan;Ukwakha ubudlelwano bokubambisana neMagna International Inc.

- Ngo-2013 Sethula imishini ethuthuke kakhulu.

- Ngo-2016, Kwethulwe imishini emikhulu ye-CMM kanye nemishini ye-CNC ye-axis engu-5;Isebenzisana namaphrojekthi we-OEM Ford Aqediwe iPorsche, iLamborghini kanye neTesla CF.

- Ngo-2017, Ukuthuthela endaweni yamanje yezitshalo;I-CNC inyuswe kusuka ku-8 kuya ku-17 amasethi.Kwasungulwa iTop Talent Automotive Fixtures & Jigs Co.Ltd

- Ngo-2018, Isebenzisana ne-LEVDEO yezimoto futhi yaqeda umugqa wokukhiqiza wezimoto.4-axis high-speed CNC yethulwa, isamba seQty se-CNC safinyelela ku-21.

- Ngo-2019, i-Dongguan Hong Xing Tool & Die Manufacturer Co., Ltd yasungulwa.(Isevisi yokumisa eyodwa) Isebenzisana noTesla Shanghai kanye neSodecia Germany.Yakha ilabhorethri entsha ye-R&D yokuzenzakalela.

- Ngo-2020, Isebenzisana ne-OEM ISUZU e-SA ;Iqedele i-RG06 One-Stop Service.

- Ngo-2021, Ukuqhubekela phambili ngenkolelo yekhwalithi yokwakha ibhizinisi elisezingeni lomhlaba.

- Ngo-2022, ihhovisi leqembu le-TTM lasungulwa eDongguan City, i-New CNC 4 axis*5 amasethi, i-New Press* amathani angama-630, i-Hexagon Absolute Arm.

- Ngo-2023, i-TTM yakha isitshalo esisha sokuhlola ibhizinisi lokulungisa izinto zokushisela;ukwengeza umshini owodwa we-2000T.

I-Check Fixture & Welding Jigs Factory (Ingqikithi yendawo: 9000m²)

Amathuluzi Okunyathela Nezimboni Zokufa Nezingxenye Zomshini (Ingqikithi yendawo: 16000m²)

Incazelo Yemikhiqizo

| Igama Lomkhiqizo | I-Welding Fixture |

| Isicelo | I-CCB yezimoto, i-Front End, i-WS Spring Link, i-Front Bumper njll. |

| Uhlobo lwe-Welding | I-Spot Welding, i-Arc welding, (i-CNC/Assembly) Isilungiselelo sokushisela esikhethekile |

| I-Pneumatic Component Brand | SMC, FESTO, TUENKERS, CKD, Manual clamp |

| Electrical Component Brand | OMRON, Mitsubishi, Siemens, Baluff |

| Okubalulekile(Vimba, Iphinikhodi yendawo) | 45# Insimbi, Ithusi, Insimbi Engagqwali |

| Indlela yokusebenza | I-Robot Welding, i-Manual Welding, i-Special machine welding |

| Indlela Yokulawula | Isilawuli Somoya(Ivaluvu Yokulawula Umoya), Isilawuli Kagesi(Ivaluzi Ye-Solenoid), Imanuwali, Ayikho i-valve ye-solenoid edingekayo Nikeza iswishi yesixhumi |

| Indlela Yokubamba | I-Pneumatic, Manual |

| Indlela Yokuxhumana Ngeseli Welding | I-EtherCAT, PROFINET, CC-LINK |

| Ibhokisi Lokudluliswa Kwezokuxhumana | Indlela ye-wiring yebhokisi likagesi, uhlobo lwesokhethi esheshayo, uhlobo lwesiqhingi se-Solenoid valve |

| I-Welding Fixture Base Type | Kulungiswe phansi, iPositioner/Flip Tye |

| Piping Way | Ishubhu lesendlalelo esisodwa, ishubhu elibushela ilangabi, Ishubhu yethusi/Insimbi engagqwali |

| I-Fixture Surface Treatment | Ukupenda, Ukupenda+I-Black Oxidization, I-Zinc-Coated, I-Powder Painting |

| Isikhathi esiholayo | Amaviki angu-2-4 wokuklama nokubuyekezwa komklamo; Amaviki angu-10-12 okukhiqiza ngemva kokugunyazwa kokuklama Izinsuku ezingu-7-10 zokusebenza zokuthutha emoyeni; Amaviki angu-4-5 okuphuza ulwandle |

| Die Life | Kuncike kumthamo wokukhiqiza wekhasimende |

| Umshwalense Wekhwalithi | Ukuhlolwa kwe-CMM Hlola ngamasampuli I-Onsite Buy-Off Ividiyo eku-inthanethi Yokuthenga Inkomfa Yewebhu Thenga-Off Ukuxazulula Izinkinga |

| Iphakheji | Amabhokisi Okhuni amasampula; Amabhokisi Okhuni noma Amaphalethi okulungisa; |

Ezezimotoizinto ze-weldingzingamathuluzi abalulekile ohlelweni lokukhiqiza izimoto.Lezi zakhiwo ezikhethekile zenzelwe ukuqinisekisa ukuqondanisa okunembile kanye nokuhlanganiswa kwezingxenye ezihlukahlukene, ukusiza ukushiselwa kwe-chassis, amaphaneli omzimba, nezinye izingxenye ezibucayi.Kulo mbono obanzi, sizohlola izici ezibalulekile zemishini yokushisela izimoto, okuhlanganisa ukubaluleka kwazo, ukucatshangelwa kwedizayini, ukwenziwa, ukulawulwa kwekhwalithi, kanye nendima yazo embonini yezimoto.1. Ukubaluleka Kwezinto Zokulungisa Izimoto:

Imishini yokushisela izimoto idlala indima ebalulekile ekukhiqizweni kwezimoto ngezizathu ezimbalwa: Ukunemba: Iqinisekisa ukuqondanisa okunembile kwezingxenye, okuholela ekushiseleni okungaguquki nokunembile.Lokhu kubalulekile ekuhloniphekeni kwesakhiwo nokuphepha kwemoto.

Ukusebenza kahle: Imishini yokushisela isheshisa inqubo yokuhlanganisa, inciphisa isikhathi sokukhiqiza nezindleko zabasebenzi.Ukuqinisekisa Ikhwalithi: Ngokubamba izingxenye endaweni efanele, ukulungiswa kunciphisa ubungozi bamaphutha kanye nokukhubazeka emkhiqizweni wokugcina.Ukungaguquguquki: Ukulungiswa kuletha imiphumela engashintshi, kungakhathaliseki izinga lekhono lomsebenzisi, elibalulekile ukuze kuzuzwe ikhwalithi yemoto efanayo.2. Ukucatshangelwa Kwedizayini: Ukuklama izinto zokushisela ezimotweni kuyinqubo eyinkimbinkimbi ehilela ukucutshungulwa ngokucophelela kwezinto ezihlukahlukene: Imodeli Yemoto: Idizayini yendawo kufanele ihambisane nokwakheka kanye nemodeli ethile yemoto ekhiqizwayo.Lokhu kudinga ukuqonda okujulile kwezimfuneko zokuhlanganisa imoto.Ukuma Kwengxenye: Isakhiwo kufanele simise ngokunembile izingxenye zemoto ezihlukahlukene, njengamaphaneli omzimba, izingxenye ze-chassis, nezingxenye zohlaka.Lokhu kubandakanya izindawo eziqondile, izindlela zokubopha, nezakhiwo zokusekela.Ukubekezelelana Nokuqondanisa: Onjiniyela kufanele bacabangele ukubekezelelana okuqinile kanye nezidingo zokuqondanisa ukuze baqinisekise ukuthi izingxenye zihlangana kahle.

Ukukhethwa Kwezinto Ezibalulekile: Ukukhethwa kwezinto zokwakha kubalulekile.Kufanele iqine, imelane nokushisa, futhi iqine ukuze imelane nenqubo yokushisela.I-Ergonomics: Ukulungiswa kufanele kwenzelwe ukusetshenziswa kalula nokuphepha komqhubi.Lokhu kufaka phakathi ukucatshangelwa kokufinyelela, ukubonakala, kanye ne-ergonomics ngesikhathi sokusebenza kokushisela.3. Ukwenziwa Kwempahla:

Ukwakhiwa kwezinsimbi zokushisela izimoto kuhilela izigaba eziningana:

Idizayini ye-CAD: Abaklami bakha amamodeli anemininingwane e-3D CAD okhona, acacisa indawo, umumo, namaphoyinti okubamba ingxenye ngayinye.Ukukhethwa Kwezinto Ezibalulekile: Ngokusekelwe ekucacisweni kwedizayini, izinto zokwakha ezifanele, ngokuvamile insimbi noma i-aluminium, zikhethwa ukuze kwakhiwe into.Ukukhiqiza Izingxenye: Izingxenye ngazinye, okuhlanganisa izakhiwo zokusekela, izinsimbi, nezinto zokubeka, kukhiqizwa ngokunembile kusetshenziswa imishini ye-CNC namanye amasu akhethekile.Ukushisela nokuhlanganisa: Abashiseli abanekhono kanye nochwepheshe bahlanganisa izingxenye, baqinisekise ukuthi zihambisana ngokunembile nangokuvikelekile.Ukuhlola: Isakhiwo sihlolwa ngokuqinile ukuze kuqinisekiswe ukuthi sihlangabezana nokuhambisana nokubekezelelana okudingekayo ukuze kushiselwe okunembile.Lokhu kuhlanganisa ukuhlolwa kokulinganisa izingxenye zemoto.Ukulinganisa: Isakhiwo siyalinganiswa ukuze kuqinisekiswe ukuthi sihlala siqondana ngokuphelele futhi sigcina ubuqotho baso besakhiwo.4. Ukulawulwa Kwekhwalithi: Ukugcina izindinganiso zekhwalithi ephezulu kuyo yonke inqubo yokwenziwa kwemidlalo kubalulekile: Ukuhlolwa: Ukuhlolwa okuvamile kuyenziwa ukuze kuqinisekiswe ukunemba, ukuqina, nokusebenza kwezingxenye zesakhiwo.

Ukuhlolwa Kokubekezelela: Izilinganiso ezinembile kanye nokuhlolwa kokubekezelela kuyenziwa ukuze kuqinisekiswe ukuthi uhlelo luhlangabezana namazinga adingekayo.

Ukuqinisekiswa Kokuqondanisa: Ukulungiswa kuyaqinisekiswa ukuze kuqinisekiswe ukuthi kugcina ukuqondanisa okulungile nokuma kokuhlanganisa.5. Iqhaza Embonini Yezimoto: Imishini yokushisela izimoto iyingxenye yenqubo yokukhiqiza izimoto: I-Chassis Welding: Izinto ezilungiswayo ziqinisekisa ukuqondanisa okunembile kwezingxenye ze-chassis, okuhlanganisa izingxenye zefreyimu kanye nezingxenye ezimisiwe.I-Body Panel Welding: Abamba amaphaneli omzimba, njengeminyango, ama-hoods, nama-fenders, endaweni efanele yokushisela, okunikela ekupheleleni kwesakhiwo semoto.I-Seam Welding: Izinto ezilungiswayo zisetshenziswa ekushiseleni imithungo, amalunga, nokuxhumana ukuze kwakheke izibopho eziqinile nezithembekile.

I-Welding Automation: Ezimweni eziningi, izinto zokushisela zihlanganiswa namaseli wokushisela amarobhothi ukuze kukhiqizwe ngokuzenzakalelayo, kuthuthukiswe ukusebenza kahle nokuvumelana.6. Ukwenza ngendlela oyifisayo Abakhi Bezimoto: Abakhiqizi bezinto zokushisela izimoto ngokuvamile basebenza ngokukhethekile ekudaleni izinto ezingokwezifiso eziklanyelwe izidingo eziyingqayizivele zabakhiqizi bezimoto ngabanye.Lezi zinhlelo zenzelwe ukuhlangabezana namazinga nezimfuneko eziqondene nomkhakha othile, futhi zingaguqulelwa kumamodeli ezimoto ahlukene ngaphakathi komugqa womkhiqizo womkhiqizi.Sengiphetha, ukulungiswa kwe-welding yezimoto kuyingxenye ebalulekile yenqubo yokukhiqiza izimoto.

Izixazululo(Turnkey Solutions Service)

I-Body In White Assembly Systems:

1, Qedela Ulayini Wokushisela Umzimba Wemoto

2, I-Single Stand-yodwaIseli Lokushisela

3,I-Welding Fixtures kanye namaJigs:

I-CCB ASSYI-Welding Fixture, Floor Pan ASSY Welding Fixture, Wheelhouse ASSY Welding Fixture, AB Ring ASSY AB Welding Fixture, Seat ASSY Welding Fixture, Front Seat Cross Member Welding Fixture, Front End ASSY Welding Fixture, Dash Panel ASSY Welding Fixture, Cowl ASSY Welding Fixture kanye neRocker ASSY Umkhiqizi we-Welding Fixture, inkampani yokuklama kanye nefektri.

ISO Management System For Welding Fixture

Ithimba lethu le-Welding Fixture

Izinzuzo Zethu

1.Isipiliyoni esicebile ekukhiqizeni okuzenzakalelayo nokuphathwa kwebhizinisi.

2.Isevisi ye-One Stop yethuluzi lokugxiviza, indawo yokuhlola, izinto zokushisela namaseli ukuze kuzuzwe isikhathi nokongiwa kwezindleko, ukunethezeka kokuxhumana, ukukhulisa inzuzo yamakhasimende.

3.Ithimba lonjiniyela elizophothula i-GD&T phakathi kwengxenye eyodwa nengxenye yokuhlanganisa.

I-4.Turnkey Solution Service-Stamping Tool, Ukuhlola I-Fixture, I-Welding Fixtures kanye namaseli neqembu elilodwa.

I-5.Ikhono eliqinile nokusekelwa kobuchwepheshe bamazwe ngamazwe kanye nokubambisana ngokubambisana.

6.Umthamo omkhulu: I-Check Fixture, i-1500 amasethi / ngonyaka;I-Welding Fixture namaseli, amasethi angu-400-600 / ngonyaka;Amathuluzi wokunyathela, amasethi angama-200-300/ngonyaka.

Sinabasebenzi abangaphezu kuka-352, u-80% wabo onjiniyela abakhulu bezobuchwepheshe.Uphiko lwamathuluzi: abasebenzi abayi-130, isigaba se-Welding fixture:abasebenzi abangama-60, Isigaba sokubheka izakhiwo: abasebenzi abayi-162, Sinethimba elichwepheshile lokuthengisa nokuphatha amaphrojekthi, amaphrojekthi wesikhathi eside wesevisi yaphesheya kwezilwandle, ukusuka ku-RFQ kuya ekukhiqizeni, ukuthunyelwa, ukuthengisa emva kokuthengisa, ithimba lethu ingasingatha zonke izinkinga zamakhasimende ethu ngesiShayina, isiNgisi nolimi lwesiJalimane.

Isipiliyoni Semiklamo Emikhulu Yamaseli Welding Nokulungiswa Kwezinto Zokushisela

| Iphrojekthi Enkulu Yokulungisa Ukushisela(2019-2021) | |||||

| Into | Incazelo | Uhlobo | Igama lephrojekthi | Ubuningi(Amasethi) | Unyaka |

| 1 | I-CCB WF | I-Arc Welding | I-VW MEB31 | 60 | 2019-2021 |

| 2 | I-CCB WF | I-Arc Welding | I-VW MEB41 | 10 | 2020 |

| 3 | I-CCB WF | I-Arc Welding | VW 316 | 4 | 2020 |

| 4 | I-CCB WF | I-Arc Welding | Ford T6 | 8 | 2021 |

| 5 | I-CCB WF | I-Arc Welding | ISUZU RG06 | 3 | 2020 |

| 6 | I-CCB WF | I-Arc Welding | Imoto, BSUV | 6 | 2020 |

| 7 | I-CCB WF | I-Arc Welding | I-Bcar, BCAR | 7 | 2020 |

| 8 | I-Floor Pan WF | I-Sopt Welding | SK326/0RU_K Karoq RU | 15 | 2019 |

| VW316/5RU_K Tarek RU (19003) | |||||

| 9 | I-WS Spring Link WF | I-Arc Welding | I-WL/WS | 4 | 2019 |

| 10 | Abakaki be-Crossmember WF | I-Arc Welding | I-WL/WS | 12 | 2019-2021 |

| 11 | Ibhampa yangaphambili i-WF | I-Arc Welding | VW281 | 14 | 2019 |

| 12 | I-Chassis WF | I-Arc Welding | ISUSU RG06 | 18 | 2019 |

| 13 | I-SL ASY ne-MBR kanye ne-EXT ASY | I-Spot kanye ne-Arc Welding | Ford P703 | 25 | 2019-2021 |

| 14 | I-CCB WF kanye Neseli Esebenzayo | I-Arc Welding | ISUSU RG06 | 6 | 2020 |

| 15 | I-Front Seat Cross Member | I-Sopt Welding | I-Volkswagen AG MEB316(20001) | 4 | 2020 |

| 16 | I-Floor Pan WF kanye ne-Grippers | I-Sopt Welding | I-AUDI/ PORSCHE PPE 41(19017 Isigaba 1) | 18 | 2020 |

| 17 | Wheel House WF kanye Grippers | I-Arc Welding | I-Ford BX755(19018) | 6 | 2020 |

| 18 | AB Ring WF kanye Grippers | I-Arc Welding | I-Ford BX755(19018) | 14 | 2020 |

| 19 | Dash Panel WF kanye Grippers | I-Sopt Welding | I-South Africa Ford T6(17028-1) | 10 | 2020 |

| 20 | Cowl WF kanye Grippers | Spot Welding | I-South Africa Ford T6(17028-3) | 6 | 2020 |

| 21 | Front End WF kanye Grippers | I-Spot kanye ne-Arc Welding | I-South Africa Ford T6(17025) | 10 | 2020 |

| 22 | I-Rocker WF kanye ne-Grippers | Spot Welding | I-South Africa Ford T6(19029) | 8 | 2020 |

| 23 | I-Floor Pan WF kanye ne-Grippers | I-Sopt Welding | I-AUDI/ PORSCHE PPE 41(19017 Isigaba 2) | 63 | 2021 |

| 24 | Ibhampa yangemuva ne-Chassis WF | I-Arc Welding | I-Ford P703&J73 | 36 | 2020-2021 |

| Iphrojekthi Enkulu Yokulungisa Ukushisela(2022) | |||||

| Into | Incazelo | Uhlobo | Igama lephrojekthi | Ubuningi(Amasethi) | Unyaka |

| 25 | I-WF Yokuqiniswa Kwesiteshi Esiphakathi | I-Sopt Welding | I-Vinfast VF36 | 8 | 2022 |

| 26 | I-Floor Pan WF kanye ne-Grippers | I-Sopt Welding | I-AUDI/ PORSCHE PPE 41(19017 Isigaba 3&4) | 39 | 2022 |

| 27 | I-Floor Pan WF | I-Sopt Welding kanye ne-Projection Welding | I-Ford P703 PHEV | 29 | 2022 |

| 28 | I-Floor Pan WF kanye ne-Grippers | I-Sopt Welding | IPorsche E4 Floor Pan(21050) | 16 | 2022 |

| 29 | Umhubhe Waphansi WF | Ukumaka nge-laser | I-VW Floor Tunnel(21008) | 2 | 2022 |

| 30 | Isihlalo se-ASSY WF ne-Tooling | I-Arc Welding | BYD Isihlalo ASSY | 40 | 2022 |

| 31 | I-Floor Pan WF | I-Spot kanye ne-Arc Welding | Ford Refurbishment | 24 | 2022 |

| 32 | I-CCB WF | I-Arc Welding | I-VW Cyclone CCB(21037) | 10 | 2022 |

| 33 | I-CCB WF | I-Arc Welding | I-VW MQB37(22022) | 16 | 2022 |

| 34 | I-A&B-Pillar WF | Spot Welding | I-Gestamp GS2203 | 8 | 2022 |

| 35 | I-Robot Cell Base | NA | I-VW Cyclone | 4 | 2022 |

Isikhungo Sokukhiqiza I-Welding Fixture

Singakha zonke izinhlobo zezinto zokushisela ezinosayizi abahlukene okuhlanganisa nosayizi omkhulu njengoba sineMishini emikhulu ye-CNC.Ngezinhlobonhlobo zemishini yemishini efana nokugaya, ukugaya, imishini yokusika izintambo kanye nemishini yokubhoboza, singakwazi ukulawula ngokuphumelelayo nangokunembile inqubo yokucubungula.

Amasethi angama-25 e-CNC aneshifu engu-2 esebenzayo

Isethi engu-1 ye-3-Axis CNC 3000*2000*1500

1 Isethi ye-3-Axis CNC 3000*2300*900

1 Isethi ye-3-Axis CNC 4000*2400*900

Isethi engu-1 ye-3-Axis CNC 4000*2400*1000

Isethi engu-1 ye-3-Axis CNC 6000*3000*1200

4 Isethi ye-3-Axis CNC 800*500*530

9 Isethi ye-3-Axis CNC 900*600*600

5 Isethi ye-3-Axis CNC 1100*800*500

Isethi engu-1 ye-3-Axis CNC 1300*700*650

1 Isethi ye-3-Axis CNC 2500*1100*800

5 I-axis CNC -Umshini

4 I-axis CNC -Umshini

Isikhungo Somhlangano Welding Fixture

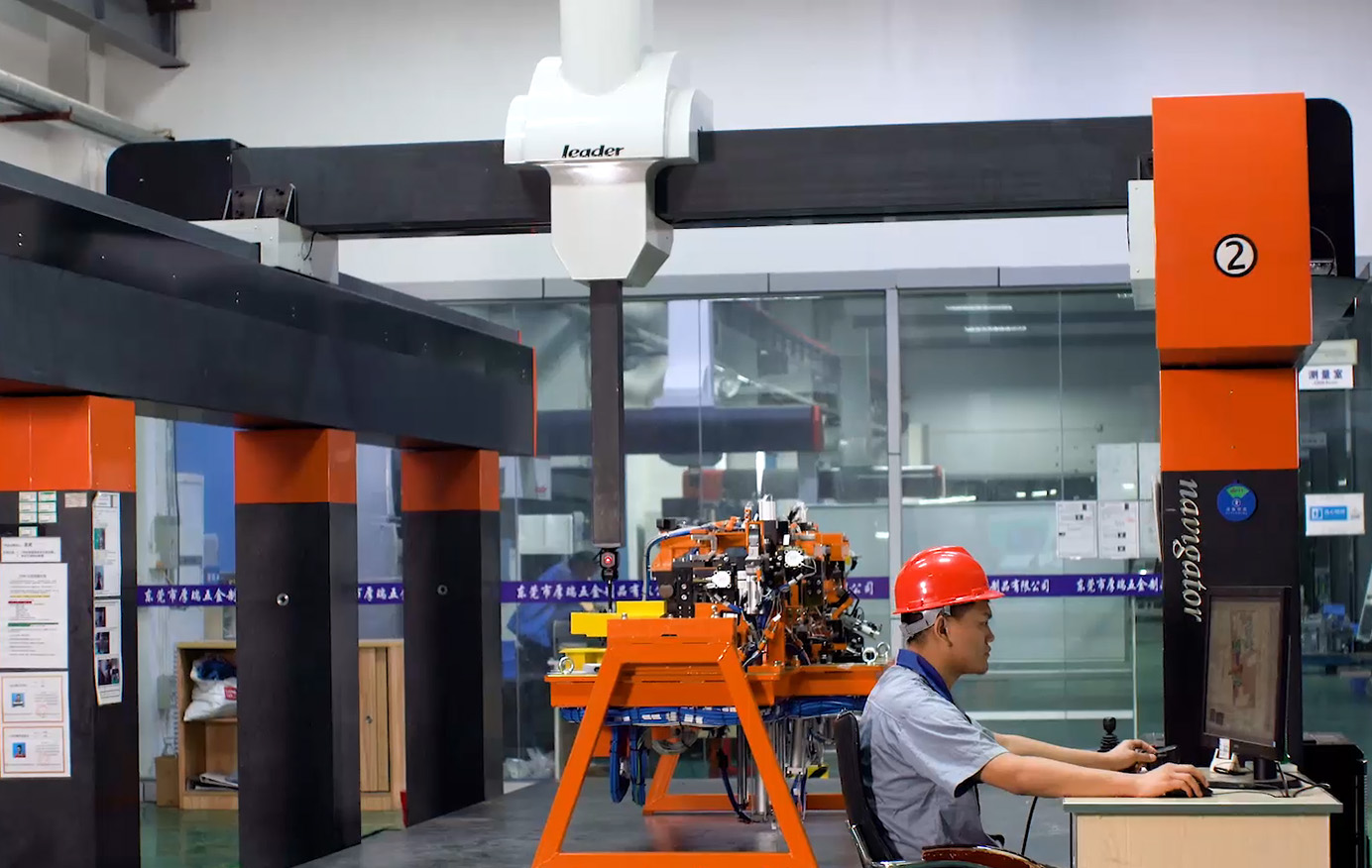

I-CMM Measurement Center Yokulungisa Ukushisela

OAbasebenzi abaqeqeshiwe bazonakekela ngaso sonke isikhathi kulo lonke uhlelo esinalo.Singenza zonke izimfuneko ezivela kukhasimende, ukuze sibe nokwaneliseka okukhulu kakhulu naku-CMM.

3 Amasethi e-CMM, 2 Shifts/Day(10hrs shift ngayinye Mon-Sat)

CMM, 3000*1500*1000 , Leader CMM, 1200*600*600 , Leader Blue-light Scanner

CMM, 500*500*400, Hexagon 2D Projector, Hardness Tester

.png)

.png)