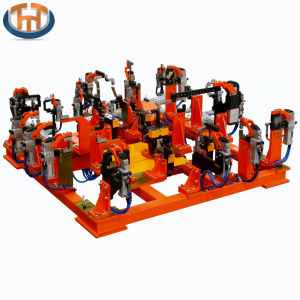

I-Al / Steel Robotic Automation Systems Welding Fixture For Automotive Part

Ividiyo

| Umsekeli Wesisekelo: | Insimbi | Impahla Yomzimba: | I-Al Nensimbi |

| Izinto zesifanekiso: | Insimbi | Isisindo: | 1035KG |

| Usayizi: | 1050*800*820mm | Umbala we-Al Nensimbi: | I-Oxidation Yangempela Noma Upende |

Ingxenye Yezimoto Ngokwezifiso I-Robot Automation Welding Jig Fixture

Lezi Zimo Zokuhlola Zombili zinesakhiwo esiyinkimbinkimbi kakhulu futhi zihlanganisa amakhulu ezingxenye.Amayunithi okuslayida namabhulokhi asetshenziswa kabi kulezi zilungiso ezimbili zokuhlola.Imikhombandlela ephindwe kabili kanye nezivalo zenza amayunithi ashelelayo azinze.

Sengeze isivalo esiqinile ukuze simise amayunithi okuslayida endaweni evulekile kanye nezikhonkwane ezigxilile ekuhloleni indawo.

Ukwenza kube lula ku-opharetha ukuhambisa le Fixture enkulu, senza kokubili ihhuku yokuphakamisa kanye namasondo avamile kulezi zindlela zokuhlola.Ukwengeza amandla e-Fixtures, sivumela amapuleti e-welding aphindwe kabili nezinkomishi eziyizinyawo eziyisishiyagalombili ezizohlinzeka ngokusekela okuqinile.Umsebenzisi angakwazi kalula ukulandelana kokubopha ngamapuleti amancane okubuyisela agxivizwe eduze kwezinsimbi.

Imininingwane yethu yokukhiqiza

| Izinto | ||

| 1 | Izinto eziyisisekelo | Al |

| 2 | Isicelo | Izitembu Izingxenye |

| 3 | Ukwelashwa kwendawo | I-Oxidation/Paint |

| 4 | Icubungula Ukunemba | 0.15 |

| 5 | Ukunemba Kwamanye Amaphrofayili | 0.1 |

| 6 | Ukunemba kwe-Datum Hole | ±0.05 |

| 7 | Isitifiketi | ISO 9001:2008 |

| 8 | Isitifiketi se-CMM | Yebo |

| 9 | Isofthiwe | Catia, UG, CAD, STP |

| 10 | Ukucaciswa | 1050*800*820mm |

| 11 | Ukupakisha | Ibhokisi Lokhuni |

Umbala

I-Base Plate Surface: Umbala Woqobo Wengqondo

Uhlaka Oluyisisekelo Oluyinhloko Nokusekela: Umbala Oluhlaza

Izingxenye Zensimbi Ne-Aluminium: I-Anodized Emnyama

Ukubekezela kokukhiqiza

1.Idethi Yendawo ±0.05mm

2.I-Surface ±0.15mm

3.Izikhonkwane Zokuhlola Nezimbobo ±0.1mm

Inqubo

CNC Machining(Milling/Turning), Ukugaya

Ukwelashwa Kwe-Black Anodized

Amahora Wokuklama(h): 60h

Ikhwalithi yokulawula

I-CMM (3D Coordinate Measuring Machine), HR-150 A Hardness Tester

Isikhathi sokuhola nokupakisha

Izinyanga ezi-2 ngemuva kokugunyazwa kwedizayini ye-3D

Izinsuku eziyi-15 ngolwandle: HMM

Ikesi Lokhuni Elijwayelekile lokuthekelisa

Inqubomgomo Yekhwalithi

Ukuhambisana Nomthetho

Ikhasimende Kuqala

Ukulawulwa Kwekhwalithi Okuphelele

Ukusebenza Kwesistimu

Ukuthuthukiswa Okuqhubekayo

Sizobambelela enkolelweni yokuthi i-TTM imele ikhwalithi ephezulu kakhulu futhi sizama kanzima ukudala ibhizinisi elisezingeni lomhlaba.

Okuningi

I-Inspection Fixtures izothunyelwa nemiyalelo yokusebenza edingekayo kanye nombiko wokuhlola we-CMM.Izembozo zothuli zizokwenziwa ngokukhethekile ukuze zivikeleke endaweni.

-300x3001.png)

-300x3001.png)

.png)

.png)